Overview

I led the UI/UX design for a custom ERP system at Fremont Automation, built to modernize their internal manufacturing operations. The goal was to connect siloed workflows, including parts, BOMs, purchasing, fabrication, and customer records, into a centralized modular interface.

Designed 15+ screens across 8 functional modules to reduce miscommunication, streamline fabrication, and automate part ordering logic. The project was handed off in near completion due to relocation.

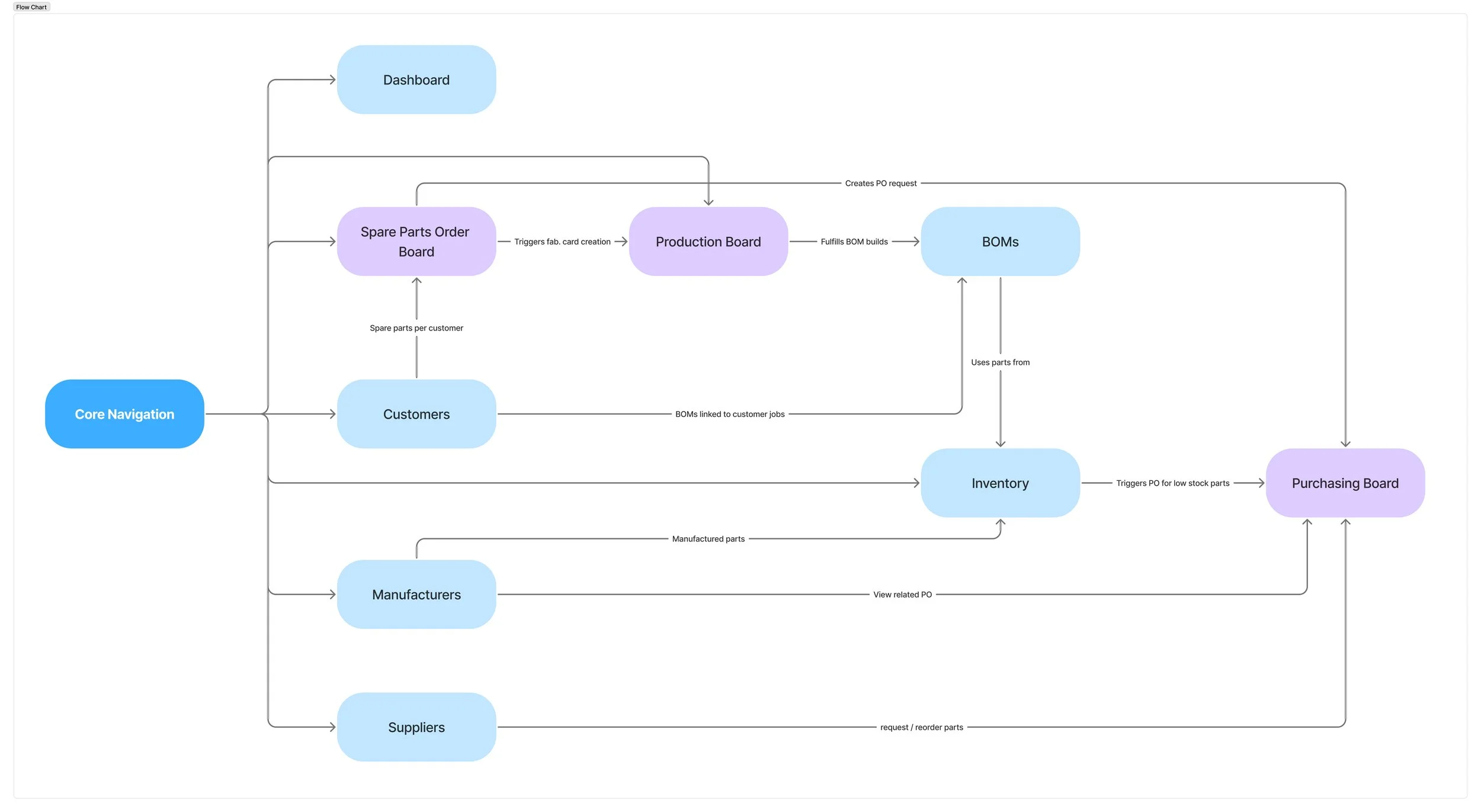

System Architecture

This architecture map shows how each module connects: Inventory ↔ BOMs ↔ Orders ↔ Fabrication Boards ↔ Customer Records. I designed with traceability and minimal click-depth in mind.

Core Functionality

One click PO triggers from inventory

BOM editor with raw material calculator

Farmed vs In-House toggles with fabrication time tracking

Engineering view for print releases

Spare part > SO > PO / Fabrication cascade

Selected Screens

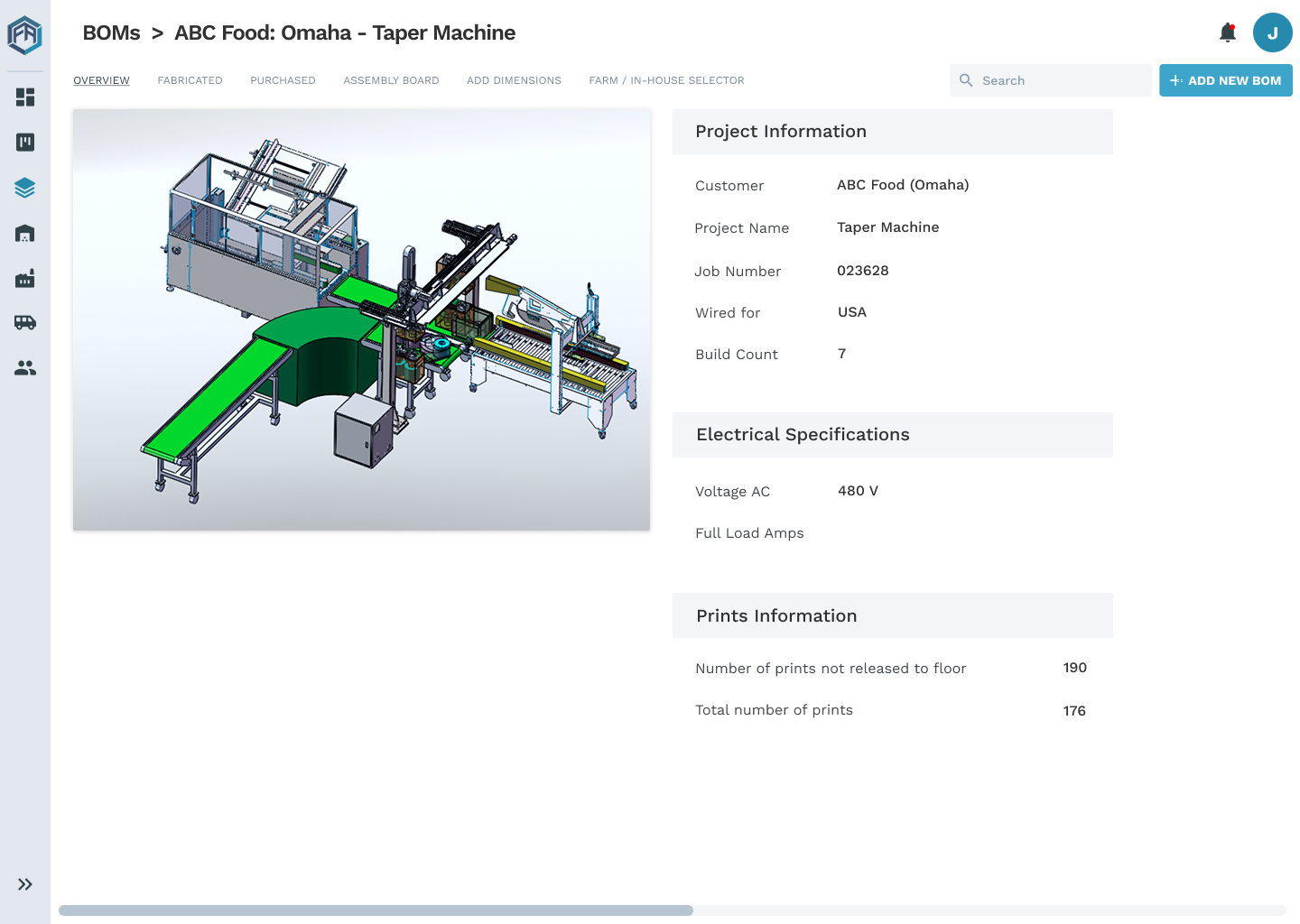

1. BOM Overview Page

A two-panel layout shows project info and CAD visualization. This screen anchors each machine job, highlighting customer specs, voltage, and print readiness.

2. Fabricated Parts Table

Live fabrication tracking by part using AG Grid — sortable table showing fabrication type, part status, stock quantity, and spare quantity. Designed to spot fabrication needs and manage spare parts quickly.

3. Spare Parts Order Board

Kanban board view of part requests. Cards move through stages (fab, ship, done) and include customer tags, delivery timing, and item count. Designed for hands-on production tracking.

* All screens show placeholder data